The Science Behind Baltic Pharmaceuticals’ Steroid Development

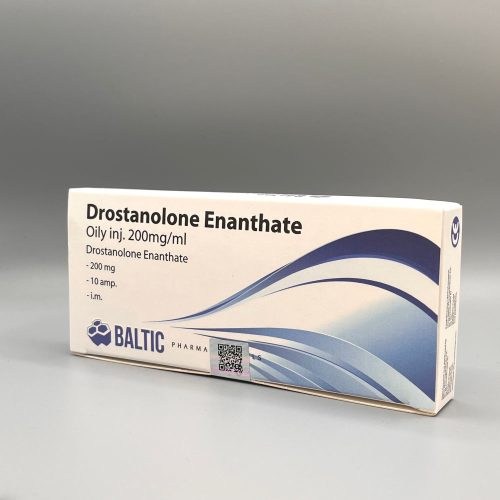

Baltic Pharmaceuticals has established a strong reputation for producing reliably formulated anabolic steroid products. For individuals seeking clarity about how these compounds are created, regulated, and tested, understanding the science behind their chemical structure, manufacturing techniques, and safety protocols is essential. The following guide breaks down the key elements that shape the performance, purity, and consistency of their steroid lineup.

Chemical Composition: How Baltic Pharmaceuticals Designs Its Steroids

The foundation of every Baltic Pharmaceuticals steroid product is its precise chemical formulation. These compounds are engineered to closely resemble naturally occurring hormones such as testosterone. By modifying molecular structures, researchers create synthetic steroids that reinforce anabolic (muscle-building) functions while reducing androgenic (masculinizing) side effects.

Two of the most common active ingredients include:

• Testosterone Esters: Testosterone can be chemically paired with ester chains that influence how quickly it enters the bloodstream. Forms such as enanthate, cypionate, and propionate release at different speeds, allowing users to select an option that aligns with their preferred timing, whether rapid delivery or prolonged effects is the goal. More on testosterone’s natural role in the body can be found via this overview.

• Nandrolone: Popular for its ability to support muscle development with comparatively lower water retention, nandrolone—especially nandrolone decanoate—remains a core component in many formulations. Its structure helps minimize certain common androgenic side effects.

These chemical modifications allow Baltic Pharmaceuticals to strike a critical balance between desired anabolic performance and reduced unwanted side effects. This approach aligns with scientific standards observed across the pharmaceutical and medical research sectors, as detailed by organizations such as the U.S. Food & Drug Administration.

Inside the Manufacturing Process

The creation of Baltic Pharmaceuticals’ steroid products is a multi-stage manufacturing journey that adheres to stringent quality and safety requirements. Everything begins with certified raw materials from approved suppliers, each batch undergoing purity checks before entering production.

Key Steps in Production

1. Synthesis: Active steroid molecules are chemically synthesized in controlled laboratory environments. Ester groups are attached, ensuring proper absorption once administered.

2. Purification: After synthesis, compounds are purified to remove unwanted by-products and residual solvents. Purity plays a central role in product quality and is closely monitored.

3. Formulation: The purified actives are blended with suitable carriers—often sterile oils or solvents—to create a stable injectable solution.

4. Filtration and Sterilization: Advanced filtration systems remove microscopic contaminants. Sterilization ensures the finished solution meets safety expectations and remains free of harmful microorganisms.

Throughout these stages, Baltic Pharmaceuticals follows Good Manufacturing Practices (GMP), an internationally recognized set of standards designed to protect consistency and safety. You can learn more about GMP through resources such as the World Health Organization.

How Baltic Pharmaceuticals Ensures Quality and Safety

Quality assurance drives every part of the company’s operations. From early production to final packaging, multiple layers of quality control ensure that all products meet strict specifications.

1. Raw Material Verification: All ingredients are screened for contaminants before being approved for use.

2. GMP Compliance: Adherence to Good Manufacturing Practices reduces the risk of variability or contamination in every batch.

3. Purity Testing: Each batch undergoes extensive testing to detect potential impurities such as bacteria, heavy metals, or other foreign substances. Independent laboratories assist in providing objective verification of safety and authenticity.

4. Packaging and Storage: Steroid solutions are sealed in sterile conditions and stored to prevent degradation caused by light, temperature, or humidity.

5. Batch Consistency Tests: Every batch is compared against previous production runs to ensure uniformity in potency, purity, and stability.

The Importance of Laboratory Testing

Lab testing serves as the backbone of product verification at Baltic Pharmaceuticals. These tests evaluate three primary factors:

• Contaminants: Ensures no harmful substances are present.

• Potency: Validates the concentration of active ingredients.

• Sterility: Confirms that injectable solutions are free from bacterial contamination.

In addition to internal evaluation, independent third-party laboratories play a role in certifying quality. This dual process ensures transparency and builds consumer confidence, a practice widely supported in scientific and pharmaceutical industries such as those cited by Science.org.

Why Strict Quality Control Matters

Quality control protects users from the potential risks of poorly manufactured steroid products. Low-quality or contaminated compounds can lead to ineffective results or serious health concerns. Baltic Pharmaceuticals mitigates these risks by implementing rigorous safety measures across production stages.

• Potency Accuracy: Every batch is checked to ensure consistent results.

• Authenticity Protection: Anti-counterfeit protocols help safeguard buyers.

• Contamination Prevention: Clean manufacturing environments and sterile packaging minimize health risks.

By enforcing these standards, the company ensures that users receive products that align with expected performance and safety guidelines.

Conclusion

Baltic Pharmaceuticals remains committed to producing reliable, high-quality anabolic steroid formulations through scientifically driven chemical design, controlled manufacturing environments, and rigorous testing. Whether used for athletic purposes or personal fitness goals, understanding how these products are created offers valuable peace of mind. With strict GMP adherence, third-party verification, and advanced production techniques, Baltic Pharmaceuticals maintains a consistent focus on safety, purity, and effectiveness.